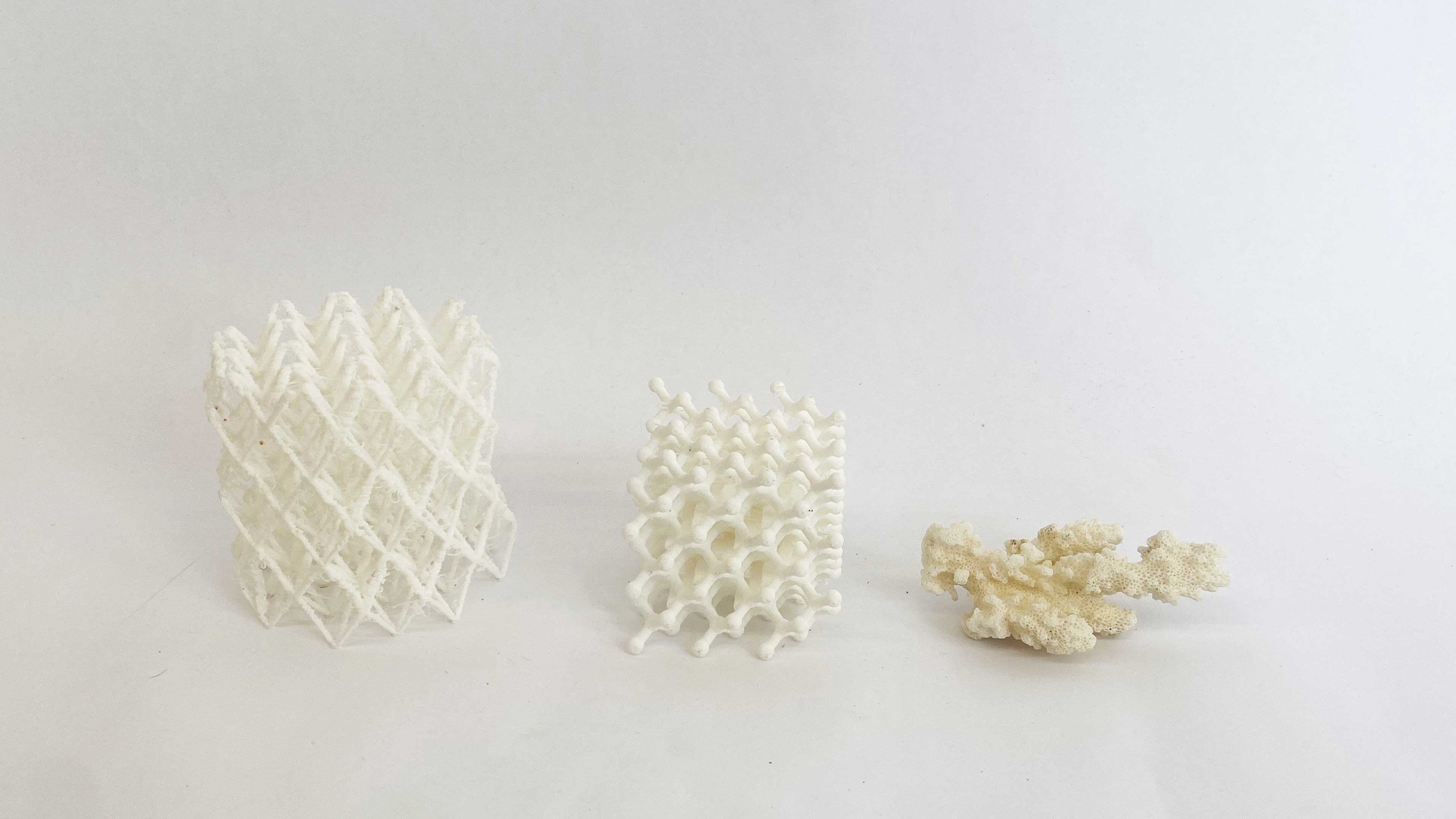

American design studio Doppelgänger, driven by Charlotte Böhning and Mary Lempres have addressed the prevalent plastic waste crisis in their recent material innovation Chitofoam. The material, analogous to polystyrene foam, is a bioplastic version of the same made from the exoskeletons of Styrofoam-eating mealworms. Shock-absorbent, water-resistant and impressively versatile, Chitofoam can be moulded into cups as well as different forms packaging and can decompose easily in a matter of weeks, unlike the controversial plastic it aspires to replace. “As a duo, we bonded over a shared interest in material innovation and the use of waste as a raw material to inspire regenerative solutions that support circular economic models. We both worked at regenerative farms as volunteers and observed how the concept of “waste” in natural systems is very different than the man-made one,” share Böhning and Lempres. “As designers, we feel inspired to create behavioural changes and foster healthy interactions between people and waste,” they add.

Traditional expanded polystyrene constitutes a staggering 30% of landfill debris and is rarely recycled, ending up as microplastics in the soil and the oceans. When discussing the omnipresence of plastic and the role design plays in its mitigation, there is frequent mention of ‘circular system design’, an approach that takes into account the entire lifecycle of an object. Chitofoam, conforming to this approach, provides a circular design solution for Styrofoam waste management. “We believe that we are entering a new design era where life-centered design will take precedence and all design will be reconsidered to evolve and promote all life forms. This shift will happen subtly through the implementation of smart, seemingly invisible design infrastructure,” Böhning notes. “In taking soft synthetic plastics, feeding them to mealworms, and making a new bioplastic out of the byproduct, we were exploring circularity and bioremediation in tandem,” she adds.

The creation of Chitofoam, a concoction of science, technology and creativity, begins with the “small, but mighty” mealworms and their intriguing ability to digest one of the most fatal man-made contaminants with ease, owing to an enzyme in their gut. Moreover, these mealworms are also the source of chitin, the polymeric basis for Chitofoam. “Chitin can be sourced from a number of different organisms, but we wanted to highlight the mealworms due to their curiosity-provoking ability to eat and digest synthetic soft plastic waste,” says Lempres. At the end of the mealworms’ life cycle, they are removed from the biodigestor and chitin is extracted from their exoskeletons.

“Chitofoam is still in its early stages. We are still researching the applications, modifying the material and thinking of ways to scale production alongside economic incentives for growth,” share the duo. With their stirring creativity, they have broached a necessary conversation about sustainable material alternatives, reiterating that most solutions the world looks for are present abundantly around us in nature and its intriguing processes. Chitofoam remarkably tackles two goals in tandem: fighting plastic pollution and developing a sustainable replacement of the ubiquitous material.

Sign in with email

Sign in with email

What do you think?