With the globe waging a war with the mammoth carbon footprint stifling the environment imperceptibly, the construction industry stands tall as an infamous antagonist. Global cement production contributes to a staggering 7% of annual greenhouse gas emissions, dominantly through the burning of quarried limestone. Amidst the tightening reins of carbon emissions, the University of Colorado Boulder spearheads a research team that has devised an innovative carbon neutral—and even carbon negative—technique to produce cement, by extracting carbon dioxide from the air with the help of microalgae.

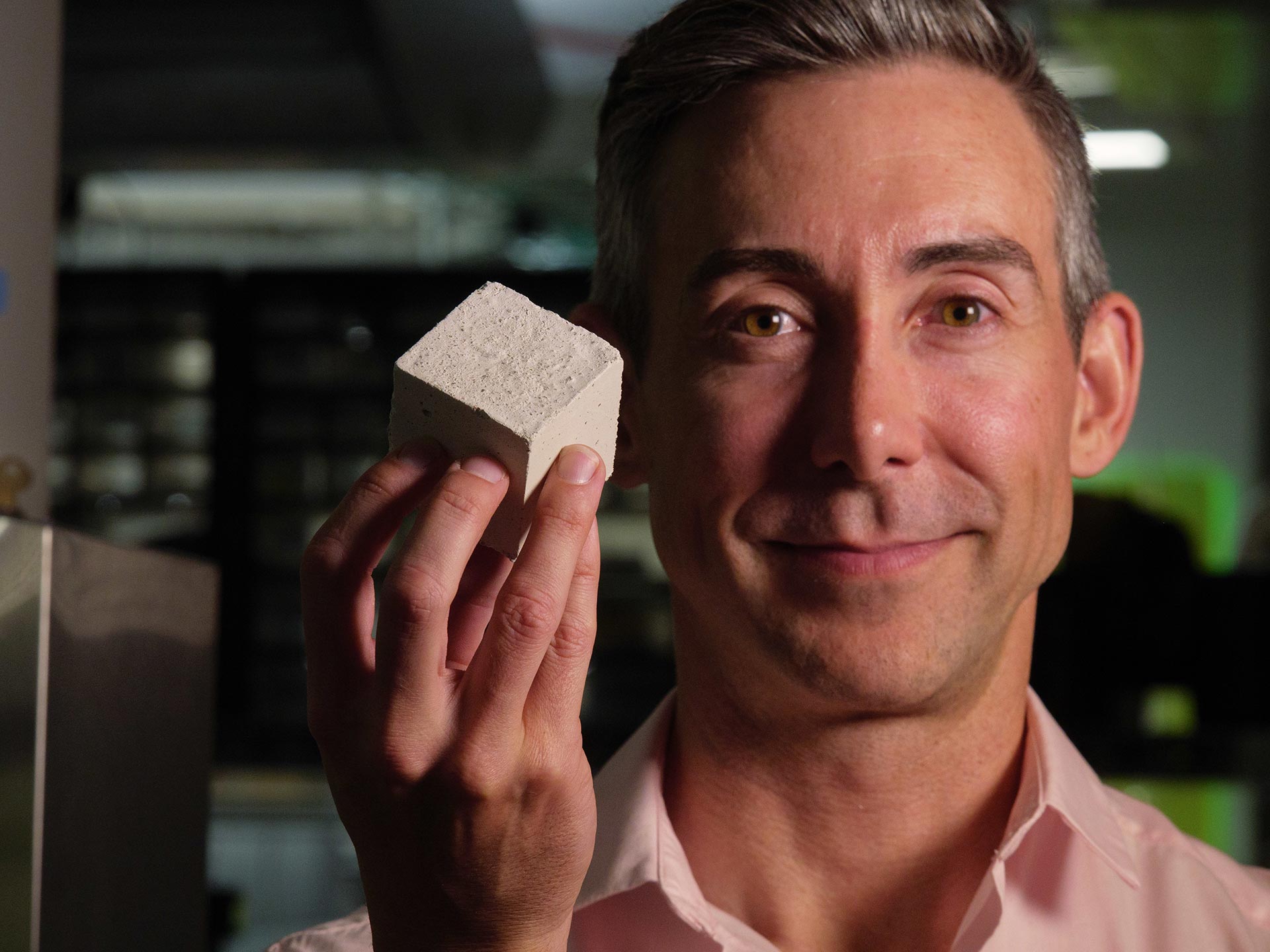

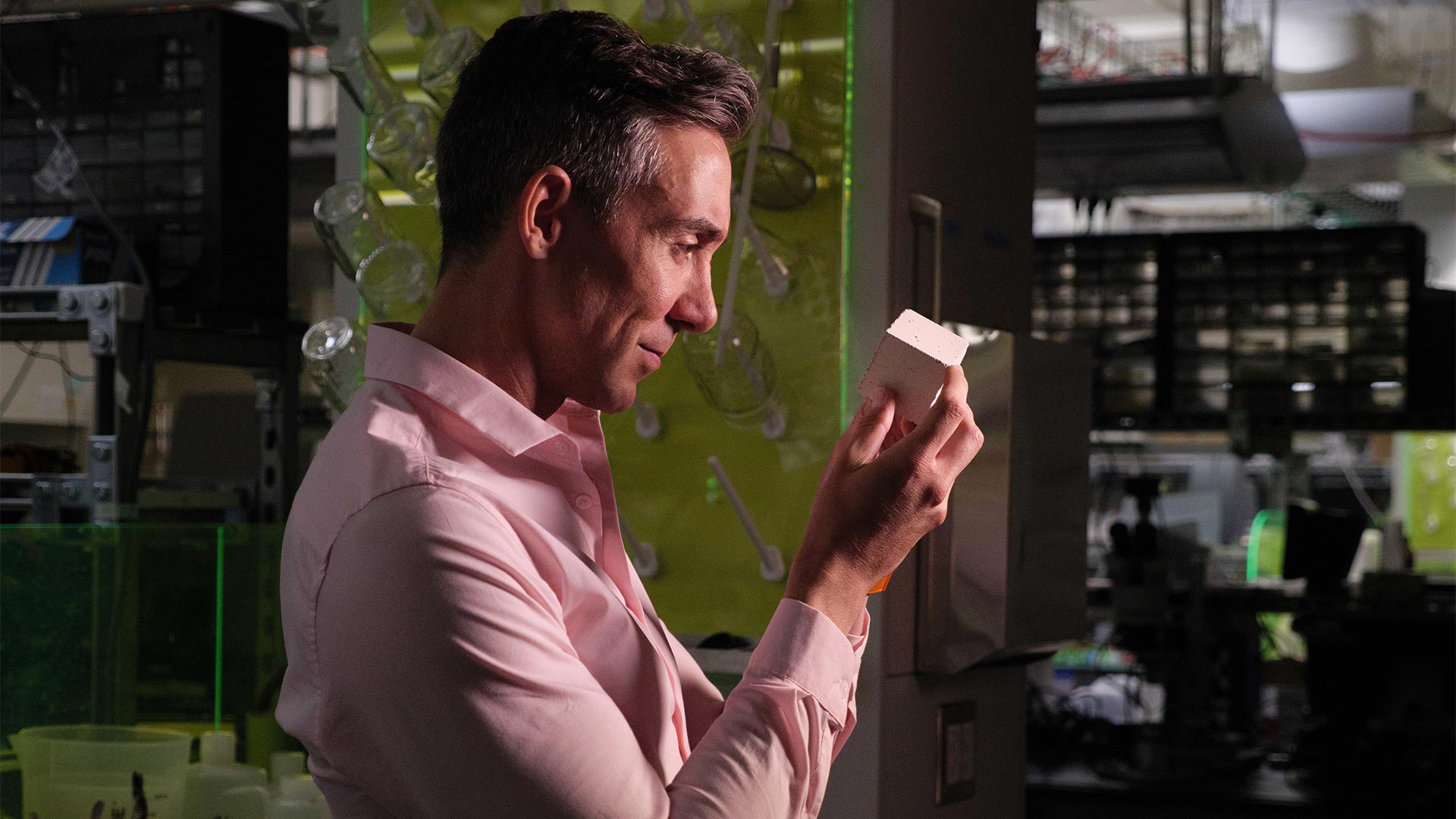

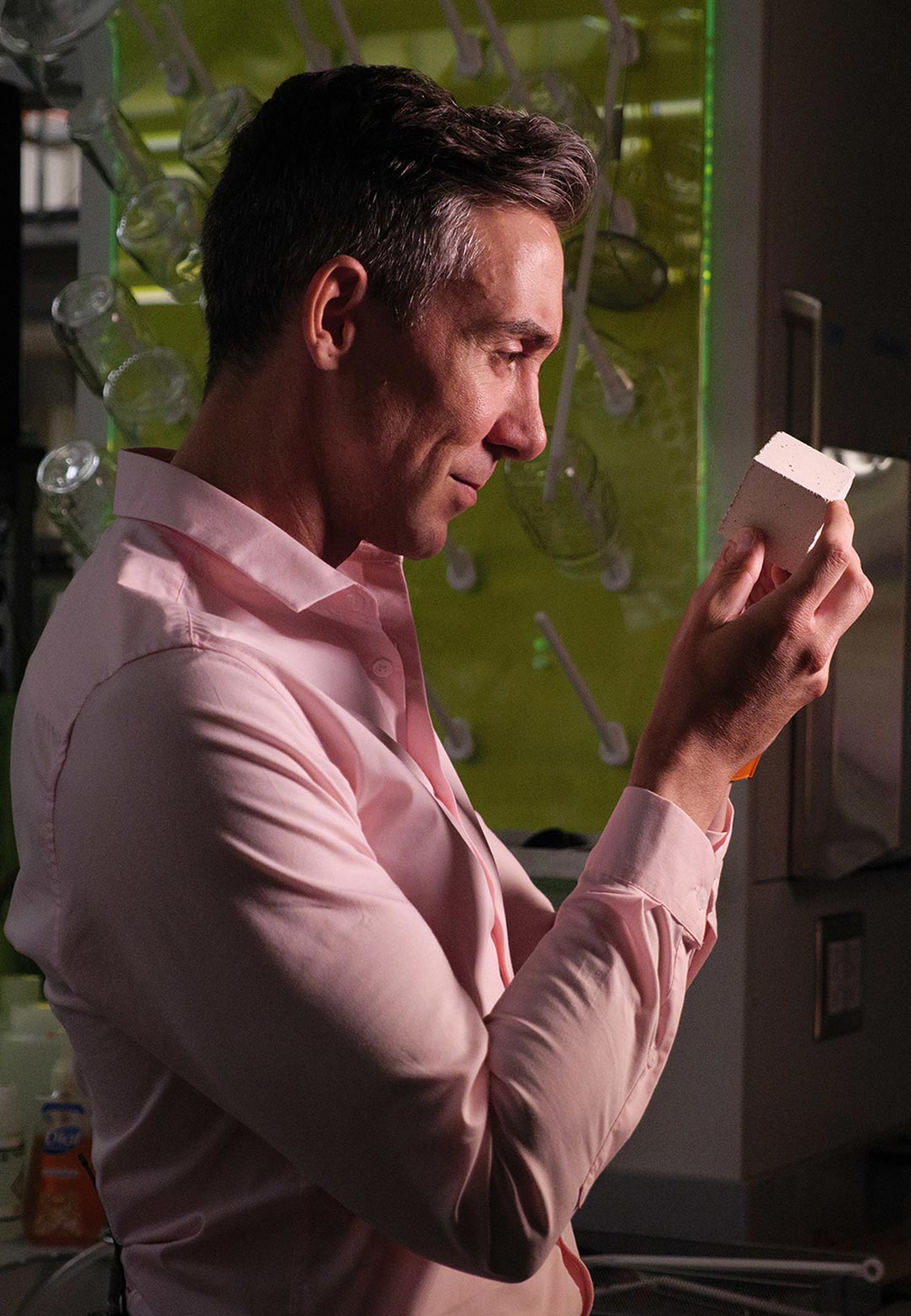

The CU Boulder engineers who worked in partnership with the Algal Resources Collection at the University of North Carolina Wilmington (UNCW) and the National Renewable Energy Laboratory (NREL) have received a $3.2 million grant from the U.S. Department of Energy’s (DOE) Advanced Research Projects Agency–Energy (ARPA-E) for their inventive endeavour. The research team was also chosen by the HESTIA program to expand and escalate the production of biogenic limestone-based portland cement and stride towards a zero-carbon future. “This is a really exciting moment for our team,” says Wil Srubar, lead principal investigator on the project and associate professor in Civil, Environmental and Architectural Engineering and CU Boulder’s Materials Science and Engineering Program. “For the industry, now is the time to solve this very wicked problem. We believe that we have one of the best solutions, if not the best solution, for the cement and concrete industry to address its carbon problem,” he adds.

During the manufacture of Portland cement, limestone, the most prevalent form of cement, is derived from quarries and incinerated at high temperatures, unleashing an immense quantity of carbon dioxide. Research led to the revelation that adopting biologically grown limestone in lieu of the quarried limestone achieves a net carbon neutral way of making portland cement, that is, the carbon dioxide released into the atmosphere and what the microalgae seize are in equilibrium. Calcium carbonate, the main constituent of limestone, is continually concocted in nature in coral reefs and by some species of calcareous microalgae. Nature, a muse as always, plants a simple question in Srubar’s inquisitive mind: If nature can grow limestone, why can’t we? “There was a lot of clarity in what I had to pursue at that moment,” says Srubar. “Everything I've done since then has really been building up to this,” he continues.

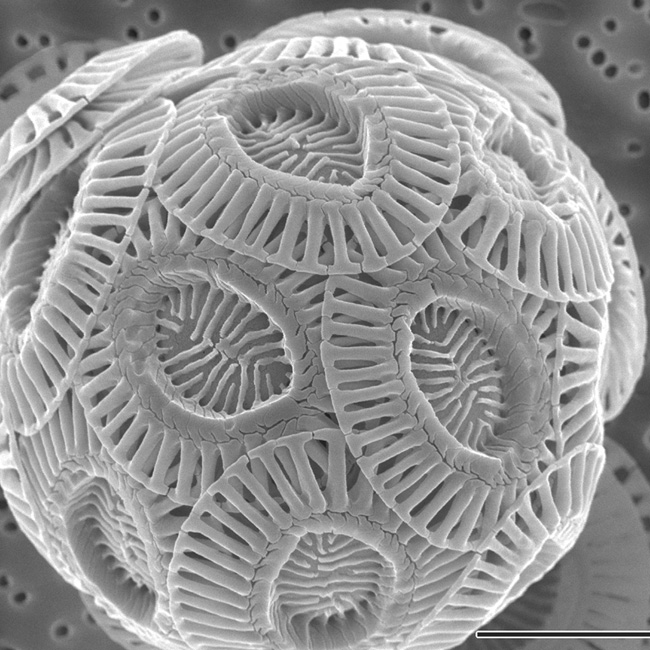

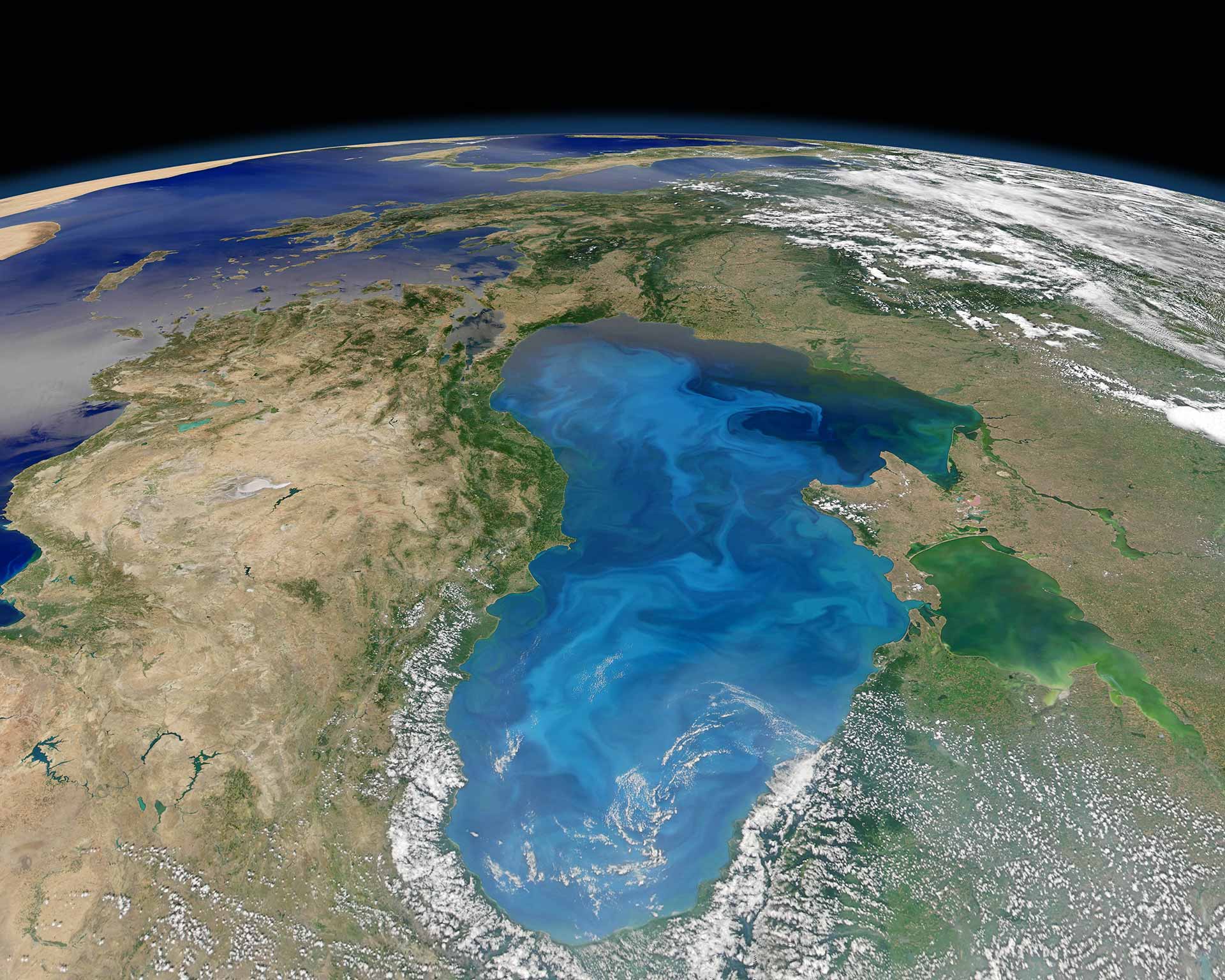

Along with his team, he pioneered the breeding of coccolithophores, cloudy white microalgae with blooms in the oceans massive enough to be seen from space—that isolate and accumulate carbon dioxide in mineral form through photosynthesis. With a meager desideratum of sunlight, seawater and dissolved carbon dioxide, these microscopic beings produce the largest amounts of new calcium carbonate on the planet, overpowering coral reefs in rapidity. “On the surface, they create these very intricate, beautiful calcium carbonate shells,” says Srubar. “It's basically an armor of limestone that surrounds the cells,” he explains. The limestone and what these organisms create in real time are only separated by a few million years.

What makes these microalgae a great contender is their ubiquity, in both warm and cold, salt and fresh waters around the world, allowing cultivation almost anywhere in cities, on land, or at sea. Based on the team’s calculations, only 1 to 2 million acres of open ponds would be required to produce all of the cement that the U.S. needs between 0.05% and 0.10% of total land area in the U.S. and merely 1% of the land used to harvest corn. Furthermore, these microalgae could also be a source of other by-products for instance the microalgae’s lipids, proteins, sugars and carbohydrates that can aid production of biofuels, food and cosmetics, redeeming the costs of limestone production. Srubar, the head of the Living Materials Laboratory at CU Boulder, has co-founded a start-up called Minus Materials to introduce this algae-grown limestone to the global market.

The current growth chart of global construction is overwhelmingly steep. But Srubar translates this ever-increasing pace into an opportunity to remodel buildings into carbon sinks and to detoxify the construction industry. A step towards sustainable construction, this version of limestone aims to enhance air quality, curb environmental damage and ensure impartial access to building materials across the world. If cement-based structures were replaced with biogenic limestone cement, the atmosphere can be saved from two gigatons of carbon dioxide and more than 250 million additional tons of carbon dioxide would be pulled out and stored in these materials. “We make more concrete than any other material on the planet, and that means it touches everybody's life,” Srubar points out. “It's really important for us to remember that this material must be affordable and easy to produce, and the benefits must be shared on a global scale,” he concludes.

Sign in with email

Sign in with email

What do you think?