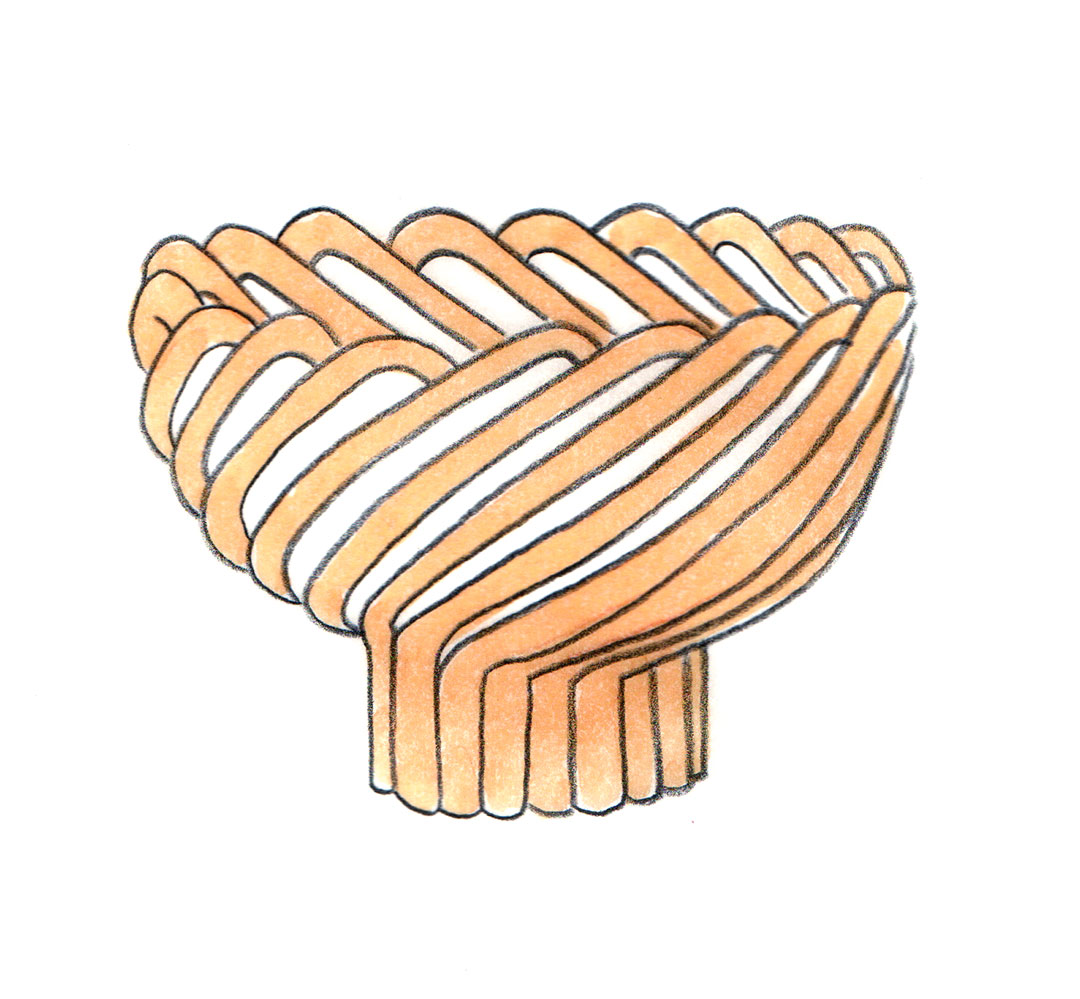

Lauded for its properties as a relatively sustainable and biodegradable material as well as a renewable resource, wood lends itself to a variety of applications throughout the realm of contemporary design, beyond its ubiquity in historic design traditions from the world over. However, the processes involved in the harvesting, treatment, and manufacture of wood occasionally end up yielding by-products that may not find immediate circular design applications or as recycled products. Confronting the pertinent challenge of upcycling waste generated through these processes, Yves Béhar-led fuseproject has partnered with Forust, a subsidiary of Desktop Metal—who specialise in 3D-printing systems - to deliver a collection of homeware that has been fabricated from wood waste. The collection, dubbed ‘Vine,’ features no adhesives or connecting members in its assembly, with each piece composed of cylindrical rods that twist upwards from a single extrusion point.

Sawdust and bioresin are the predominant materials used in the creation of the collection’s uniquely crafted products, which include a vessel, bowl, basket, and tray. In this vein, the collection and the processes used to realise it make valuable additions to the sustainable design ecosystem involved in reusing wood waste. The collection is among the earliest applications of Forust’s high-speed 3D-printing process that employs binder jetting—a method which combines a powder-based material that is layered using an adhesive binder to create solid forms in a rapid additive manufacturing process.

In developing Vine, the team at the San Francisco and New York-based industrial design and branding firm elected to adhere to an organic design language that echoed the natural growth of trees in nature. This approach emerged from their explorations into how they could make best use of Forust’s technology, arriving at a design comprising cylindrical rods of identical diameter that curve and contort upwards from a single extrusion point to define convex shapes through a simple repetitive pattern. Furthermore, the rods themselves have been spaced out in a manner that affords the pieces a sense of permeability and lightness. Despite this, the functionality and durability of the structure and materials are said to be on par with that of conventional wood products.

Even though crafting the pieces involves the rendering of complex geometries, their underlying structures possess a degree of simplicity that aids in streamlining the manufacturing process. Consequently, this method of fabrication can easily render forms that would prove to be quite challenging to realise through traditional woodworking techniques. The absence of connecting elements and adhesives also supplements the clarity encompassed within the collection’s design, by virtue of its near-homogenous materiality. Additionally, the finishes of the rods can be imparted with a plethora of natural wood grains by Forust’s 3D-printing system, permitting their textures and profiles to exude a subtle naturalistic quality that highlights Vine’s intrinsic ties to its source material.

Following their previous collaboration with Desktop Metal to develop the design language and user experience for their Studio System that 3D-prints metal, this latest venture by fuseproject in association with Forust, is a pertinent attempt to bring true circularity to the ecosystem of manufacturing wood products. At a time when upcycled design, biodegradable design, and zero-waste manufacturing are pivotal concerns in addressing the climate crisis, Vine shows that there is no need to compromise on aesthetics, structural experimentation, or functionality in product design endeavours that employ recycled materials.

Sign in with email

Sign in with email

What do you think?