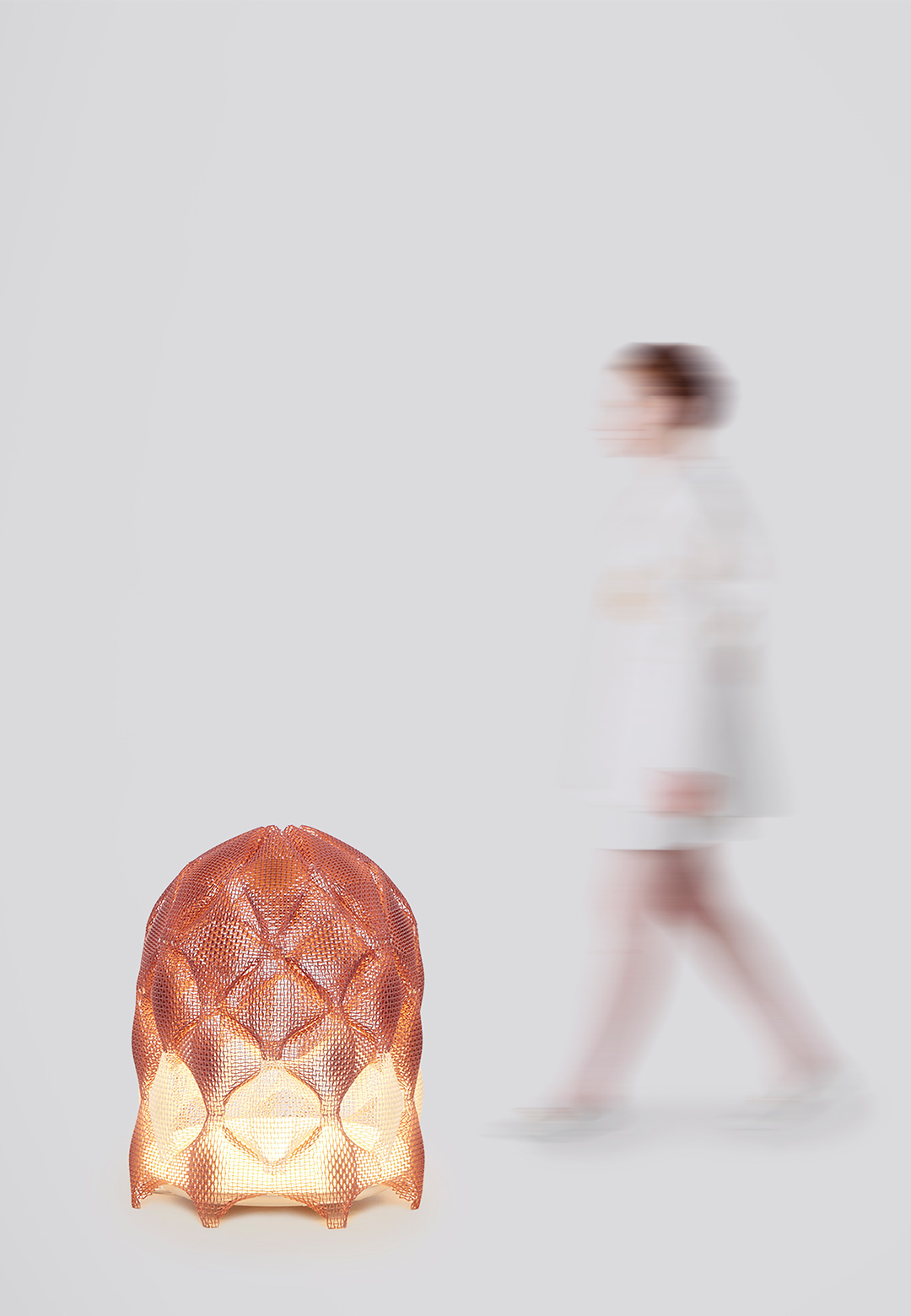

Taiwan-based industrial designer Sung Ai Tsai’s Prinx lamps are modular lighting fixtures that bear a unique geometric tactility. Made by assembling three distinct 3D-printed components, the lamps can be configured in varying shapes and sizes. The consistent tessellations on the surface of the final lamp structure, and its overall curvilinear form imbue the Prinx lamps with a sculptural quality. Although they are modular designs, their organic form gives the impression that these entities are atypically constructed, and, hence, bear the potential of featuring as bespoke pieces that can be placed in indoor environments to enhance the ambience and look of the said space.

Tsai employed the usage of auxetic structures to design the three components that make up the two floor lamps. “My inspiration is derived from auxetic structures, which possess mechanical properties that cause them to expand in the vertically stretched direction when subjected to impact,” Tsai shares. An auxetic structure possesses a negative Poisson's ratio, which, in simple terms means that it is easier for such structures to undergo volume changes, while still resisting any change in shape. This ensures that the final lamp pieces can stand sturdy, without any inflection in their shapes due to the application of pressure upon them. The auxetic structure of the three modules has high shock absorption and is fracture-resistant, as well. It is for this reason that such structures are used to make sports equipment and protective medical gear. On the other hand, the usage of an auxetic structure ensures that the individual components can still easily be manipulated to sit in conjunction with the desired form of the lamp design.

Another attribute that the 3D printed PLA components embody is varying thickness across its different parts. This eases the process of bending and turning them in specific directions. While the thicker areas of the modules are stiffer and have a smaller bending amplitude, the thinner areas are more flexible and have a larger bending amplitude. In all three modules, the structural distribution in the middle area is horizontally oriented, which enables ease in performing transformations in the form of the structure. “Through redesigning the arrangement of these units and utilising 3D printing, I have investigated how the arrangement and density of units impact their ability to expand and contract. Ultimately, I have identified rules governing the transition from the structure's 2D form to its 3D form, leading to the design of modular components,” the Taiwanese designer shares.

“Prinx is an innovative modular lighting fixture that leverages 3D printing techniques and structures to challenge traditional fused deposition modelling printing,” the product designer shares. In the first prototype of Prinx, Tsai attempted to assemble structural modules into hexagonal units, however, the joints of the individual components did not fit smoothly against each other in this version. The revised version of the product design comprises a modified assembly of the modules, hence enabling smooth vertical and horizontal interconnections. “The end design consists of three modular pieces that can flex into various shapes due to their distinct structural arrangements, facilitating the assembly of diverse versions,” the designer shares. Tsai printed out colourful modules in order to construct the two floor lamps. The strategic usage of subtle hues of blue and crimson helps the 3D-printed product integrate well into people’s lives.

Tsai’s design is unique and boasts plenty of creative potential, despite being 3D printed and modular. “Prinx exemplifies the potential of 3D printing to push the boundaries of design and engineering while showcasing the artistry and skill of its designers,” reads an excerpt from the press release. Since each of the three modules can be bent and appended to construct lamps of desired forms, they offer the user unique and easy flexibility, and the freedom to play with the modules to construct an atypical form.

Sign in with email

Sign in with email

What do you think?