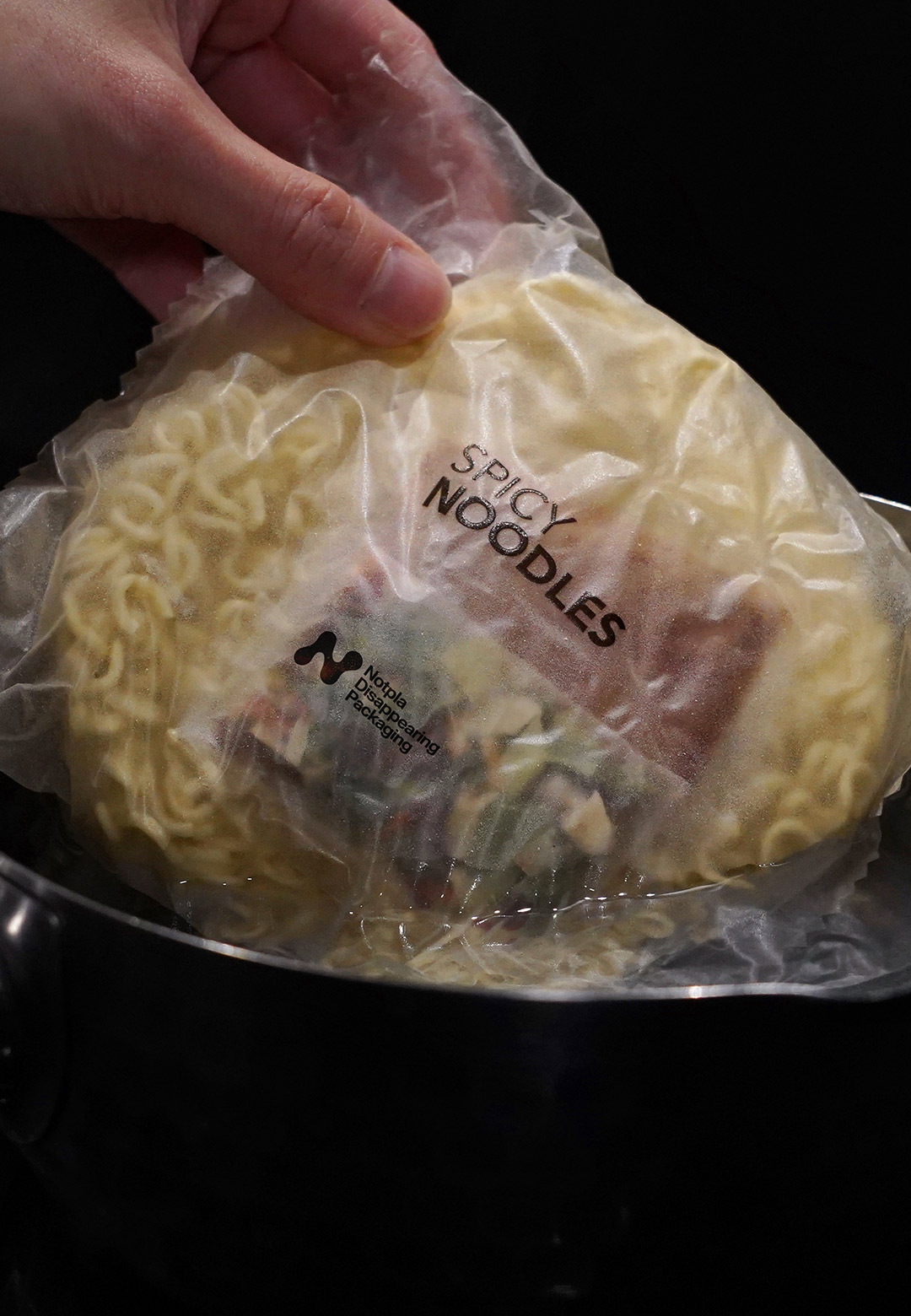

London-based Notpla’s mission statement reads: “We make packaging disappear.” If there’s one biomorphic design principle that could prove truly beneficial for the environment, it would probably entail mimicking the simple ways in which each natural entity manages to exist within a safe shell, and yet, never leave behind any kind of non-perishable waste. This seems to be the exact idea that Notpla, a sustainable regenerative packaging practice in the United Kingdom, seems to emulate via their range of disparate innovations. From food and drink containers to packaging for skincare and haircare items, each product prototyped by the British practice is designed to disintegrate in different ways. The brand majorly experiments to provide packaging solutions for several everyday applications.

“Plastic pollution has become one of the biggest threats to our environment and future. Since so much of it is created by the packaging industry, we realised there is a way of tackling the problem head-on: by creating next-generation packaging solutions that can transform the industry. Studying nature and her cycles, we find it inspirational how nothing is ever wasted,” the makers at Notpla share. At the core of Notpla’s procedure for significant change and impact are three pillars, namely Biomaterial Innovation, System Change and Renewal at Scale.

To herald the first step, Notpla brings together an interdisciplinary team of experts in material science, engineering, biology and biodesign. The team continues to produce ingenious solutions by utilising natural entities such as seaweed and plants. The result is a variety of packaging, some of which can be eaten, others can be composed, dissolved or recycled. The second step, System Change, attempts to make nature-based packaging the new normal. Notpla does this by collaborating with major sports events, meal delivery services and various businesses, all in the bid to inspire sustainable options. Additionally, Notpla also advocates for policy change and grassroots efforts to expand their impact. “Consumer education, myth-busting and anti-greenwashing are part of our key activities, to support the public in making choices that benefit everyone,” Notpla adds.

Lastly, the intent of Renewal at Scale is to upscale sustainable practices such that they can reach industrial scale and become available to everyone. With innovations such as pipettes, sachets and more, Notpla aims to fight plastic addiction with the pledge to replace 1 billion units of plastic by 2030. “Leaning on seaweed and plants as our allies, we can expand this process globally while remaining fully sustainable. Our projections show that if we were to replace all single-use plastic with seaweed, only 0.066 per cent of the ocean would be needed, which is well within safe ecological boundaries,” Notpla delineates.

While conventional food containers have petrol-based coatings that stick around forever, the simple and sturdy containers designed by Notpla are created with a 100 per cent natural seaweed coating. The containers, after usage, can be composted. They are designed to disappear without any trace, just like fruit and vegetable peels. By using seaweed as the coating material, the designers also ensure that the process is non-extractive and instead, regenerative. Seaweed is a quickly growing algae that doesn’t need freshwater, land or fertiliser. Additionally, it captures the surrounding carbon and makes the water less acidic. Seaweed forests also help filter out pollution from human activities. Hence, the more they grow, the more the benefits. Upon discarding the seaweed-coated containers, they become food for living organisms such as worms, fungi and microbes.

Another innovation by the brand is the zero-waste Notpla Ocean Paper. Unlike conventional papers obtained from virgin cellulose pulp, the Notpla Ocean Paper is a by-product obtained from seaweed processing and is characterised by its unique veining. It also has a lower Global Warming Potential (GWP) than pulp paper. Just like the containers, this paper can also be composted at home, or recycled for a second usage.

Some other innovations by Notpla include ice cream spoons and edible bubble gums, as well as transparent packaging for various foods. The usage of seaweed persists throughout all of Notpla’s products for the simple reason that it is a flexible, strong and versatile material. It can take on many shapes. Notpla’s edible water bubble prototype, called Ooho, is made of seaweed that can be eaten. By utilising the same properties of seaweed, Notpla also creates food packaging and pipettes that are edible. Designed to hold oil, Notpla’s pipettes are not only edible but also compostable at home. The bath oil and shampoo sachets by the brand, still in their prototyping phase, promise to release their contents and disappear.

In addition to the disparate products manufactured by Notpla, the brand also hosts a series of narrative stories on the subject of sustainability and regenerative designs, on its website, in a bid to educate and drive change at all levels.

Sign in with email

Sign in with email

What do you think?