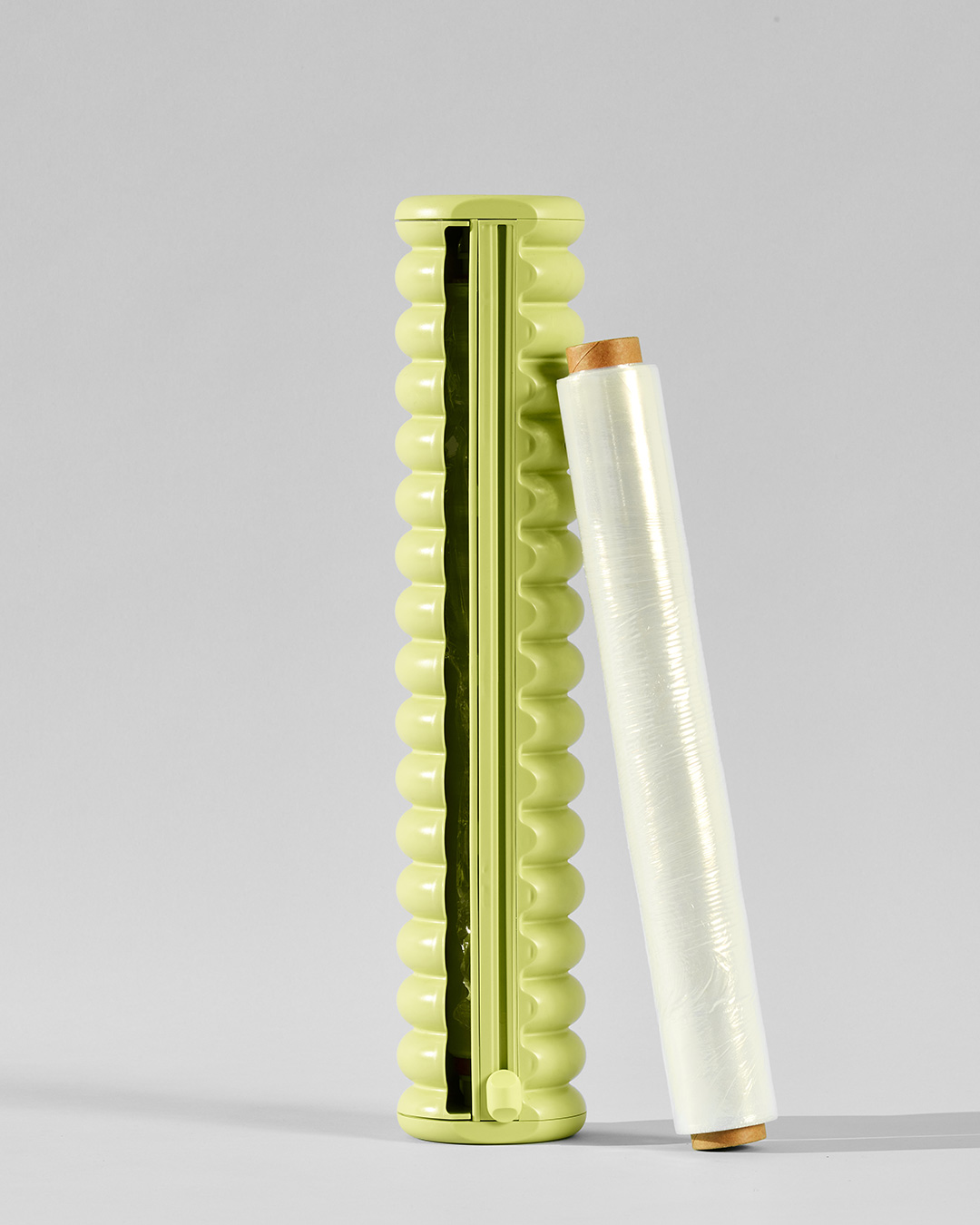

‘Greenwashing’ has ironically developed into a problem as dire as that of plastic waste itself. How many times do we come across products that make hefty claims of being eco-friendly yet arrive at our door enveloped in plastic wrap and packaging? Julia and Jordy Kay, CEOs and co-founders of the Melbourne-based biomaterials company Great Wrap, turned their awareness of the problem into a long-overdue design solution: a sustainable alternative to petroleum-based cling wrap. The company is Australia's first and only manufacturer of a certified home compostable cling wrap derived from potato waste. Their latest innovation in product design is Great Mate, a refillable dispenser for their stretch wrap, made from 33 recycled PET bottles. Great Mate is designed to clothe the cling wrap rolls and ensure their seamless extraction and usage, while extending on the company’s sustainable approach. "We saw a materials revolution happening around us. Everything was changing rapidly; energy, transport, and agriculture, yet plastic stayed the same," share the co-founders of Great Wrap. "We knew the technology existed to put an end to plastic waste, but there weren’t any products available on the market for us to use," they add.

Great Wrap’s core creation, their biomaterial cling film, is a blend of potato waste and other compostable biopolymers that make the end product 100% compostable. A globally shared love for potato chips makes potato waste an abundant resource. A significant number of skins and potatoes that fail to qualify for chips make the cut to produce a bioplastic that develops into Great Wrap. The wrap will degrade in a home compost in less than 180 days at the end of its life cycle. Amidst bioplastics that call for intensive agriculture or industrial composting conditions, Great Wrap provides a solution that is creative, pragmatic, and, most importantly, less effort-intensive. "Since we started Great Wrap, we always felt like the experience of cling wrap use was nondescript," says Julia. "We thought if we’re putting all this work into reinventing materials, why can’t the user process be memorable too," she adds.

Great Mate dispenses and slices Great Wrap’s cling wrap while curbing plastic pollution and the excessive dependency on single-use packaging. The dispenser is devised by former architect and Great Wrap co-founder Julia Kay and manufactured by a team of engineers and industrial designers at Bayly Group. The honey stick-like tactile design of Great Mate is a culmination of a process that is equally conscious of sustainability and design language. The ergonomic design features enhanced functionality, reduces the impact on waste systems and caters to the growing market of refillable, reusable and recycled products. "We see Great Mate as a storytelling vessel, the real magic is the compostable cling wrap inside," shares Julia. "We’ve come up with a way to engage and delight users that may not typically be drawn to a product like ours," the product designer adds.

Akin to its comrade, the compostable stretch wrap, Great Mate is manufactured locally in Melbourne, a decision that allows control of the entire manufacturing and design process. Every step is an active intervention to ensure a process that refrains from harming the planet and reduces greenhouse gas emissions that are frequent by-products of international production and shipping. "The team has been on a product development journey for the past 12 months and are launching their newly formulated wrap simultaneously with Great Mate," says Jordy Kay, co-founder of Great Wrap.

A staggering 373 million plastic water bottles are discarded in Australia every year. Out of all the plastic bottles that are placed into recycling, merely 36% get recycled. An overwhelming quantity of plastic ends up in landfills, waterways, and the environment, releasing toxins that imperceptibly stifle the planet as it decomposes. "We’re trying to end the vicious landfill cycle that is inevitable once someone chooses to drink from a PET drink bottle. So we’re not only on a mission to end the creation of new non-compostable plastics worldwide but to see plastic that’s already in our ecosystem be repurposed," explains Jordy.

With plastic being as ubiquitous as it is, material innovation alone is an inadequate countermeasure to the looming global crisis. Together, Great Mate, a upcycled design and its compostable cling film, a biomaterial innovation, represent a refreshing and ideal kinship between salvaged waste and sustainable alternatives. Plastic packaging continues to be rampantly employed by a plethora of companies owing to its accessibility in terms of economics and availability. Interventions by start-ups like Great Wrap not only hold up a beacon of hope for the future of materials and sustainable design but also epitomise the fundamental approach of ‘act local, think global.’

Sign in with email

Sign in with email

What do you think?