As vast swathes of green cover have been cleared in order to make way for urban development, there is a dire need to regreen city surfaces and facilitate the steady proliferation of flora and fauna throughout settlements. In fact, such measures could prove vital in the effort to make cities more habitable and sustainable environments that safeguard the well-being of their inhabitants—both human and otherwise. Building façades could play an important role in this process by serving as the foundation for the growth of urban ecosystems, allowing them to thrive alongside human activity. In this regard, British professional services firm Buro Happold and New York-based practice COOKFOX Architects have collaborated on a prototype for a system of ceramic façade panels that have been tailor-made to house urban wildlife and vegetation, embedding nature into the edifices of buildings through biophilic design.

The two teams were initially brought together to work on this project during the Architecture Ceramic Assemblies Workshop (ACAW) in 2021, held in Boston, USA. Annually hosted by Boston Valley Terracotta - a global leader in the terracotta industry - ACAW 2021 was the sixth edition of the event, uniting architects, engineers, designers, and manufacturers to dive into the applications of architectural terracotta. It was this platform that spurred Buro Happold and COOKFOX to explore this material’s usage on façades, beyond its implementation in roof structures or as decorative cladding. To this end, the collaborators endeavoured to create a biophilic screen wall in terracotta, which would then provide a haven for wildlife in urban areas, promoting biodiversity.

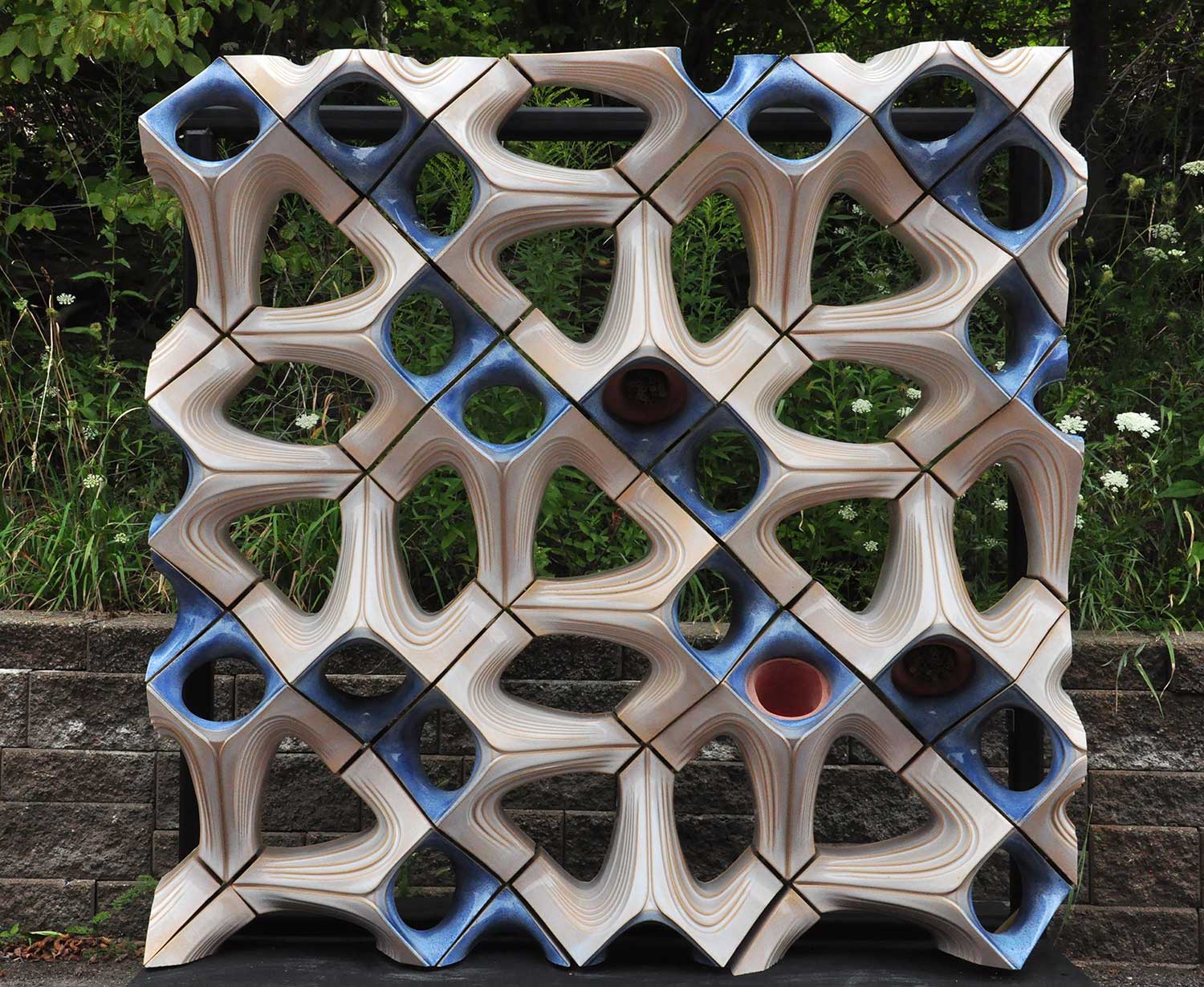

One particular benefit of working under these conditions was the absence of constraints such as client requirements, budgets, and schedules, which allowed the teams to investigate and innovate with greater freedom when compared to a standard commissioned project. Buro Happold and COOKFOX Architects initially derived influences from a host of sources, such as the façade detailing on Erwin Hauer’s architectural screen walls, Harrison Atelier’s Pollinators Pavilion, and the ornate terracotta lattices employed by Vietnam-based Vo Trong Nghia Architects in some of their projects. From these precedents, the collaborators developed a standardised stacking module by studying a plethora of geometries, patterns, and configurations, culminating in an arrowhead-shaped geometry with voids for customisation and ventilation.

Each of the modules is capable of screening sunlight and being fitted with micro-habitat pods that accommodate bees, plants, and birds respectively. While the bee pods contain tubes of varying sizes that permit native solitary bees to nest in the dozens, embedding themselves into the local ecosystem, a supplementary pod harvests water and stores it for use in a reservoir below the soil container for irrigation, and finally, native birds will find a home in the third type of pod, which has been designed to offer optimal conditions for nesting. The latter pods are also equipped with four ⅝ inch holes to allow for optimum airflow, accommodating species such as the Mountain Bluebird, Great Crested Flycatcher, Tufted Titmouse, Tree Swallow, and Chickadee. In the case of the bee pods, 8mm reeds have been provided for spring mason, wild leafcutter, wool carder, and resin bees, along with grass-carrying and mud wasps. Additionally, 6mm reeds cater to summer leafcutter bees and certain resin bees, while aphid-hunting wasps can find a home in the 4mm perforations.

Micro-habitat pods have been fabricated using slip casting, producing low-fired clay bodies that are permeable to water, allowing water to enter their volumes assisting their primary function. The surfaces of the modules are also dressed in ridges, which add texture and tactility to their designs. Larger modules in the series of prototypes were devised to either be slip cast or press moulded for the economy of scale and manufacturing. To ensure their durability and resistance to the natural elements as façade design components, the clay bodies of the modules have been made resistant to freezing and subsequent thawing, while also being configured to shrink minimally during the process of fabrication. Pigmented clays coated in custom glazes, collectively referred to as ‘engobe,’ that were developed by the design team in conjunction with the fabricators, were used to finish the system’s components.

Having initially commenced their collaborative design process in December 2020, the teams involved supervised the fabrication of test pods in Kansas City over the following summer. The modules were then transported to the Boston Valley Factory in Buffalo, New York. Finally, Buro Happold and COOKFOX Architects also gathered in August 2021 to create 24 modules of a full-scale prototype, comprising four modules for plants and bees each, alongside three modules for birds to inhabit. The modules were fastened together with the aid of stainless steel bolts and washers as well as neoprene shim plates.

Despite still being in the relatively early stages of its development, the large-scale applications of this system, once fully tested, are immense. As the holistic integration of nature into urban ecosystems could prove pivotal in the bid to make cities more sustainable and inclusive to all forms of life, Buro Happold and COOKFOX Architects’ take on this notion could potentially influence a multitude of similar efforts to make better use of all urban surfaces.

Sign in with email

Sign in with email

What do you think?